You can trust polyethylene pipe insulation to keep water out. Its closed-cell foam makes a strong wall against water and moisture. Polyethylene piping stays dry and does not get hurt by chemicals. It protects pipe insulation for many years. You get steady heat and moisture protection for hot and cold water pipes. This foam pipe insulation keeps your drinking water safe. Polyethylene insulation is great for plumbing and HVAC systems. It stops condensation and keeps its heat value even when wet.

Property | Benefit for Polyethylene Piping |

Closed-cell structure | Stops water from getting in |

Thermal insulation | Keeps heat and cold in the pipes |

Durability | Does not get damaged by moisture |

Key Takeaways

Polyethylene pipe insulation has closed-cell foam that keeps water out and pipes dry. This insulation stops moisture, chemicals, and condensation, so it protects pipes well. Polyethylene is better at keeping water out and holding heat than fiberglass and rubber. Make sure to seal all joints tight and use vapor barriers in wet places for better waterproofing. Keep polyethylene insulation away from sunlight and damage so it lasts a long time.

Waterproof Structure

Closed-Cell Foam in Polyethylene Pipe Insulation

Polyethylene pipe insulation gives strong waterproof protection. This happens because it uses closed-cell foam. Each cell in the foam is sealed off from others. This stops water and air from moving through. If you look under a microscope, you see each cell is alone. Water cannot move between these cells, so the insulation stays dry.

This closed-cell design makes a good waterproof barrier. The packed cells keep water out. You do not need to worry about leaks or water damage. Closed-cell foams take in much less water than open-cell types. Tests show closed-cell foams soak up less water, so they are great for pipe insulation.

Polyethylene piping gets many benefits from this structure:

It gives great waterproofing.

The insulation keeps heat even when wet.

Mold and mildew cannot grow inside the foam.

The barrier keeps out stains and dirt.

Tip: Closed-cell foam pipe insulation also resists many chemicals. It can handle chemicals found in plumbing and HVAC systems.

You can trust polyethylene pipe insulation to keep pipes dry and safe. The closed-cell foam gives both waterproof and heat protection.

Moisture Resistance and Water Vapor Barrier

Polyethylene piping must stay dry to work well. The closed-cell foam in the insulation blocks moisture. It keeps water vapor from getting inside. The foam’s outer skin acts as a vapor retarder. This layer lets almost no water vapor pass through—sometimes as little as 0.01 perm-in. That means hardly any water vapor gets in.

This design gives strong moisture resistance. The insulation stops water from touching the pipe. This helps stop corrosion under insulation, which can ruin pipes. The foam also stops condensation from forming. When warm air hits a cold pipe, water drops can form. The closed-cell foam keeps the pipe warm and dry, so this does not happen.

Here is a quick look at how polyethylene foam pipe insulation protects your pipes:

Feature | Benefit for Polyethylene Piping |

Closed-cell structure | Blocks water and moisture |

Built-in vapor barrier | Stops water vapor from passing through |

Low water vapor permeability | Keeps pipes dry |

Prevents condensation | Stops water droplets on pipes |

Chemical resistance | Protects against harsh substances |

Maintains thermal performance | Keeps heat or cold in the pipes |

You get more than just waterproofing. Polyethylene piping also lasts a long time. The insulation works even in wet or humid places. You do not have to worry about water getting in or hurting your pipes.

Polyethylene foam pipe insulation gives a full waterproof solution. It uses a closed-cell barrier, strong chemical resistance, and good heat protection. You can count on it to keep your pipes safe from water and other dangers.

Comparing Pipe Insulation Types

Polyethylene vs. Other Insulation

There are many kinds of pipe insulation you can pick. Polyethylene piping is special because it keeps water out very well. Fiberglass insulation is cheap and keeps heat in, but it does not like water. When fiberglass gets wet, it stops working and can fall apart. Rubber insulation bends easily and keeps water out. It fits around pipes and blocks water, but it can get damaged by sunlight.

Polyethylene insulation has closed-cell foam. This stops water from getting inside. It also blocks chemicals. Rubber insulation also has closed cells, so it keeps water out and lasts long. Fiberglass has open cells. Water can move through it, so it is not as waterproof.

Note: Polyethylene piping and rubber insulation both block chemicals well. Fiberglass does not stop chemicals as much.

Here is a table to help you compare:

Insulation Type | Waterproof | Chemical Resistance | Flexibility | Durability | Thermal Performance (Wet) |

Polyethylene | Yes | High | Moderate | High | High |

Rubber | Yes | High | High | High | High |

Fiberglass | No | Low | Low | Low | Low |

Water Resistance Differences

You want pipe insulation that stays waterproof in hard places. Polyethylene piping and rubber insulation have closed bubbles inside. These bubbles stop water from moving through. You do not need extra vapor barriers for most jobs. Polyethylene piping keeps heat in even when wet. Rubber insulation does this too. Fiberglass insulation can lose up to 70% of its heat power when wet.

Groups like ASTM and ASHRAE have rules for waterproof and heat performance. Polyethylene insulation meets these rules and gets high scores. Rubber insulation also does well. Fiberglass insulation does not meet the same waterproof rules.

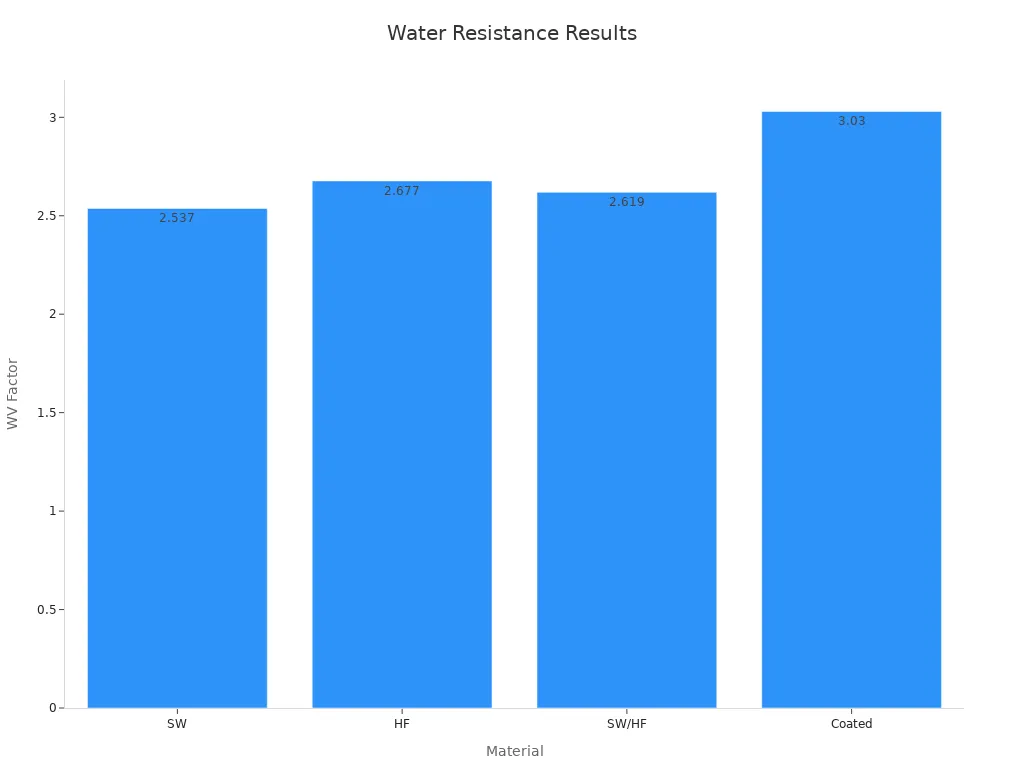

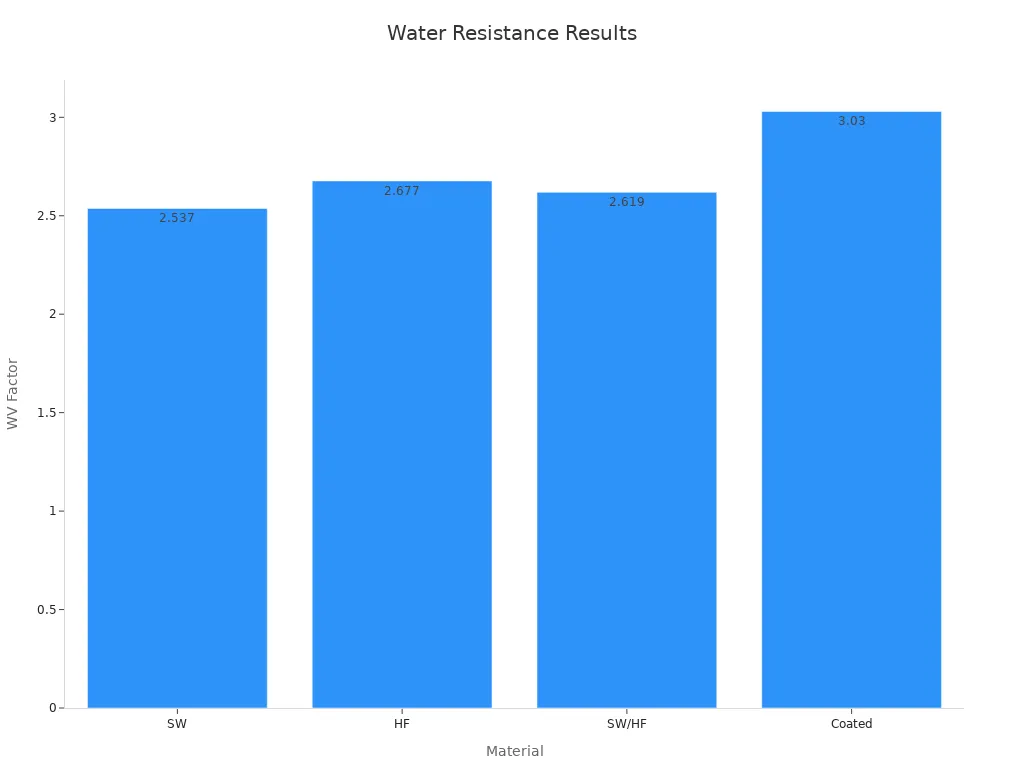

Here is a chart that shows how well each type blocks water vapor:

You can see that closed-cell types, like polyethylene and rubber, block water better than open types like fiberglass. Polyethylene piping works well in sewage and drainage systems too. It keeps water out and protects pipes from chemicals.

Tip: Polyethylene piping gives you waterproofing, chemical resistance, and heat protection all in one. You do not need to add more layers.

If you want pipe insulation that stays waterproof, pick polyethylene piping or rubber. Both give strong protection, last a long time, and keep pipes safe from water and chemicals.

Insulating Polyethylene Pipes: Installation Tips

Sealing Joints and Connections

When you put insulation on polyethylene pipes, you need to keep every joint and connection dry. If there are gaps or loose seams, water can get in. This makes the protection weaker. Always check that each piece of polyethylene insulation fits tightly. Use weatherproof glue to seal the seams. This glue keeps water from getting between the insulation and the pipe.

Many experts say you should seal every joint, edge, and connection. Companies like HydraTech LLC have shown that using special seals and wraps can stop leaks. These seals keep joints dry for many years. They use things like internal pipe joint seals and mechanical seals. These products make sure water cannot get through. These ways work quickly and last a long time.

Here are steps you can follow for the best results:

Cut the polyethylene insulation so it fits the pipe.

Wrap the insulation tightly around the pipe.

Put weatherproof glue on all seams and joints.

Press the seams together until the glue dries.

For hard spots, use extra sealing tape or a mechanical seal.

Tip: Always follow the manufacturer's instructions for sealing. This helps you get the best insulation and strong waterproofing.

Using Vapor Barriers

Polyethylene insulation blocks water, but you can add more protection for tough jobs. In places with lots of moisture or outdoor pipes, a vapor barrier helps even more. A vapor barrier is a layer that stops water vapor from reaching the pipe.

Research shows that putting a sealed PVC jacket over the insulation works well. This jacket covers the insulation and blocks holes or gaps. Water cannot get in. It also protects the insulation from bumps and sunlight. You should use a vapor barrier if you put pipes in hot, wet, or unconditioned places.

Here is a quick table to help you know when to use extra vapor barriers:

Situation | Need for Vapor Barrier? |

Indoor, dry area | Not needed |

Outdoor, exposed to rain | Yes |

High humidity (basements, attics) | Yes |

Below ground | Yes |

Note: Sealed vapor barriers lower the chance of condensation and mold. They help keep your insulating polyethylene pipes dry and safe.

By sealing all joints and using vapor barriers when needed, you make sure your polyethylene insulation stays waterproof. These steps give you strong and lasting waterproofing for all your pipes.

Limitations and Protection

UV and Weather Exposure

Polyethylene pipe insulation can be used outside or in sunlight. Sunlight has ultraviolet (UV) rays. These rays can slowly damage the outside of polyethylene. When UV rays hit the insulation, they change the material. The insulation can get weaker and less bendy. It might even crack or feel rough.

Scientists tested low-density polyethylene strips with UV light for 90 days. They saw the insulation lost strength and got more brittle. The damage was worse in air than in water or salty places. UV rays break the chemical bonds in polyethylene. This makes weak spots and changes the surface. Over time, the insulation may not protect pipes as well.

Here are the main effects of UV exposure:

Cracks and rough spots show up on the surface.

The insulation gets weaker and less flexible.

Chemical changes make the material softer.

The outside layer can turn brittle.

If you use insulation outside, add extra protection. Use a UV-resistant jacket or special paint. Cover the insulation to block sunlight. This helps keep the insulation strong and water-resistant.

Preventing Mechanical Damage

Polyethylene insulation can be hurt by cuts, holes, or crushing. In busy places or where tools are used, it can get damaged. Studies on high molecular weight polyethylene fabrics show tough covers help stop cuts and tears. These fabrics can handle lots of rubbing without breaking. But sharp things or hard hits can still break through.

A review of pipe problems shows damage can get worse over time. Small problems can turn into big ones if not fixed soon. You should check your insulation often. Look for cracks, dents, or missing parts. Replace any damaged pieces right away.

Here are some ways to protect your insulation:

Put a hard cover on pipes in busy places.

Use warning signs so people do not bump into pipes.

Check insulation every few months.

Fix or replace damaged insulation fast.

Tip: Checking your insulation often keeps it strong. This helps stop leaks, water problems, and keeps it working longer.

Polyethylene pipe insulation is good at stopping water and lasting a long time. But you still need to protect it from sun and damage. If you take care of it, your insulation will work well for many years.

Polyethylene pipe insulation keeps water out very well. It works best if you put it on and take care of it. Experts say it has some important benefits:

Closed-cell foam stops water and keeps pipes dry.

It bends easily and does not rust.

You spend less money because it lasts long and needs little fixing.

Pick polyethylene insulation for pipes in damp or wet places. This helps your system stay safe and work well for a long time.

FAQ

Is polyethylene pipe insulation completely waterproof?

Polyethylene insulation is very good at stopping water. The closed-cell foam keeps water and moisture out. It helps pipes stay dry most of the time. If pipes are outside or underground, add more protection.

Can you install polyethylene insulation on pipes outdoors?

You can use this insulation outside. But you must keep it safe from sunlight. UV rays can hurt the foam over time. Use a cover or paint that blocks UV for longer use.

How do you seal the joints for best waterproofing?

Use weatherproof glue or tape on every seam. Press the joints together so they fit tight. In wet places, wrap the insulation with a vapor barrier for extra safety.

Tip: Always read and follow the manufacturer's sealing steps.

Does polyethylene insulation help prevent pipe freezing?

This insulation helps stop pipes from freezing. The foam keeps heat inside the pipe. Pipes stay warmer if you seal all joints and use thick enough insulation.

Feature | Benefit |

Closed-cell foam | Blocks cold air |

Tight fit | Reduces heat loss |

Sealed joints | Stops moisture |